Safety and Wellbeing

Safety and Wellbeing Through Culture, Leadership and Innovation

At Nacap safety and wellbeing are integral to every aspect of our operations. Our industry-leading safety framework, the Capacity Model™, prioritises human performance and resilience, ensuring our projects are executed safely and efficiently. Accredited by the Federal Safety Commission and ISO-certified across OHS, environmental, and quality management systems, we continually uphold rigorous standards to protect our employees, clients, communities, and the environment while driving innovation and exceeding industry

best practices.

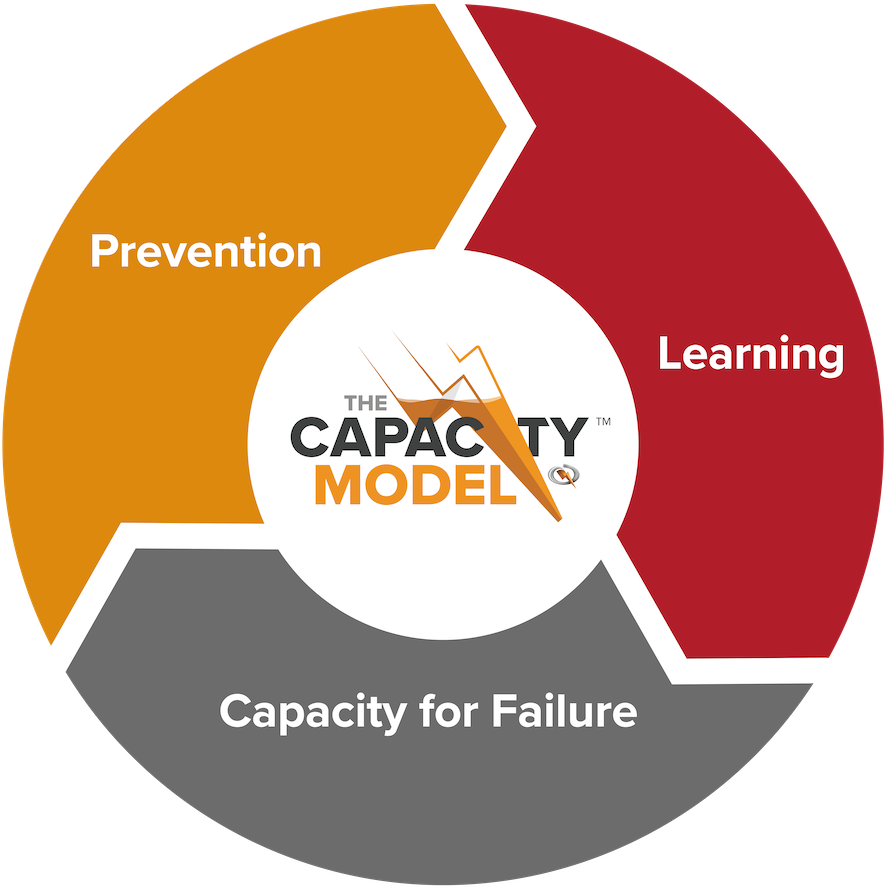

The Capacity Model™

The Capacity Model™ aims to eliminate life-threatening, life-altering, and life-ending events by focusing on human performance and building the capacity to fail safely.

Through our Capacity Model™, we prioritise human performance, building resilience to fail safely while maintaining industry-leading accreditations.

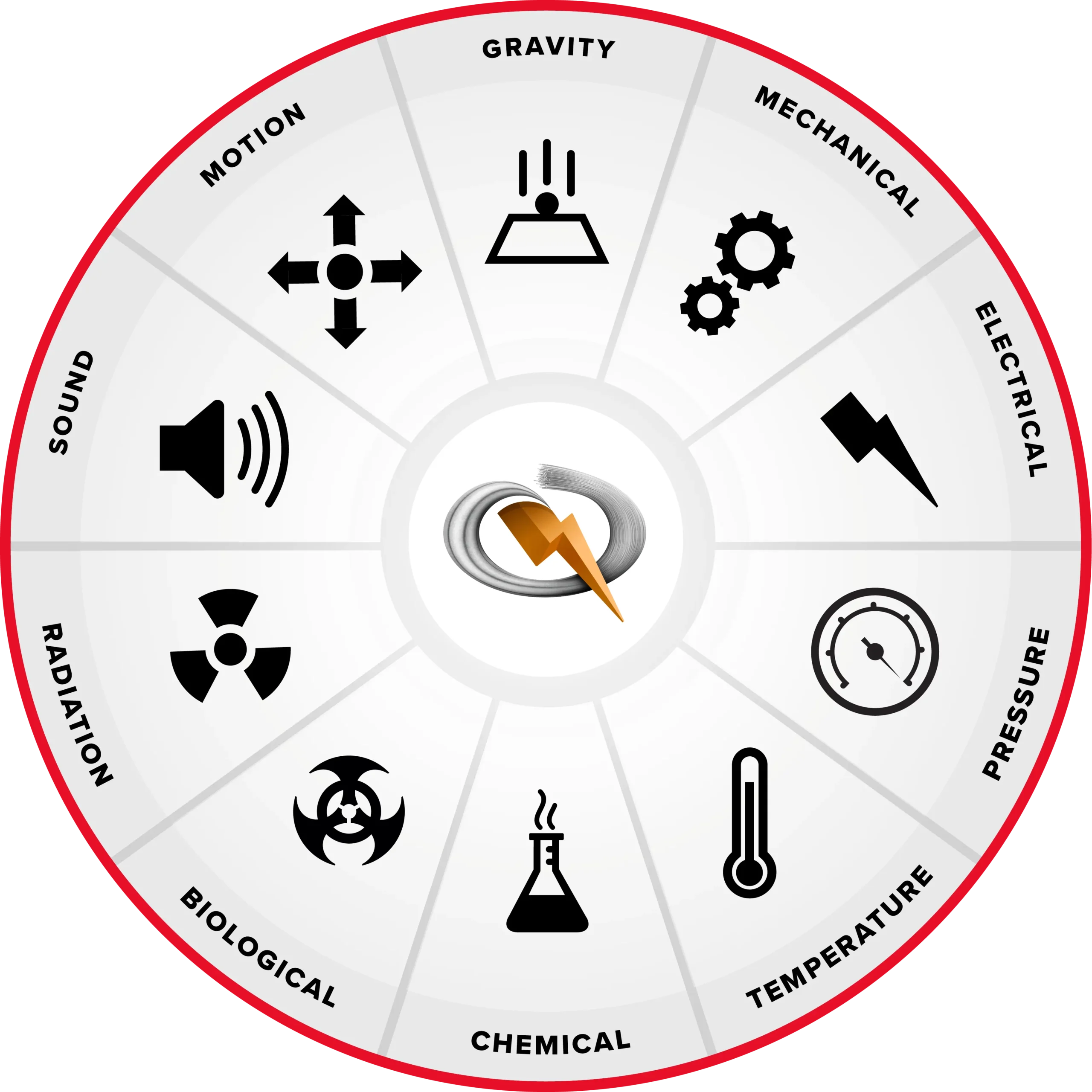

The Energy Wheel

The Energy Wheel is a hazard-identification tool that helps workers systematically evaluate the types of energy they are exposed to on the jobsite before work begins. The Energy Wheel focuses on hazards that can cause a life-threatening, life-altering, or life-ending injury, allowing our workers to build the capacity to fail safely.

Leading the Industry in Safety and Environmental Excellence

Nacap holds accreditation with the Federal Safety Commission and is a security-endorsed Defence contractor. We are ISO-accredited in OHS Management System (ISO 45001), Environment Management System (ISO 14001), and Quality Management System (ISO 9001). In high-level commitment to the health and safety of employees, customers, the community, and the environment, Nacap consistently meets all environmental regulatory requirements and maintains an ISO14001-aligned environmental management system. We seek to maintain our status as an industry leader in safety and environmental management and performance by continually assessing and improving our systems to ensure safe and reliable pipeline system operations, protect the environment, and exceed standards for industry best practice.

Safer Together

Nacap has been a long term member of Mates in Construction and Safer Together.

Mates in Construction is a charity established in 2008 to reduce the high level of suicide among Australian construction workers. MATES provides suicide prevention through community development programs on sites, and by supporting workers in need through case management and a 24/7 help line.

Safer Together is a not-for-profit, member-led organisation of oil and gas exploration, production industry operating, and contract partner companies committed to creating the leadership and collaboration needed to build a strong and consistent safety culture in our rapidly evolving industry.